Basic knowledge of foreign substances mixed in food

In recent years, news reports have increased the number of foreign matter mixed into foods, and consumers are becoming more sensitive.In many cases, major food manufacturers were discovered, fearing the spread of problems and deteriorating corporate images, and in many cases.Countermeasures against foreign matter mixed in the food industry are urgent issues.

However, in reality, it is impossible to completely eliminate foreign matters in products generated in food factories.Some manufacturers say that their target values will be reduced to 1 ppm (1 /1 million) to 1 million or less.There are factories that manufacture more than hundreds of thousands of products per day are all over the country, and we really want to aim for smaller numbers.

What should food manufacturers do for that?First, foreign substances include bacteria, viruses, mold, and chemicals as well as physical ones.All and at the same time, you need to take measures.Easy to come up with is the enhancement of rules, such as "do not do anything" and "must be in this procedure."However, the more rules, the more difficult it becomes to make everything thorough.

Therefore, in this series, we will explain a total of 10 items, including two items each time, including the mechanism to continue and strengthen foreign matter mixed entry into foods and specific measures with immediate effect.

Lottery

1st: Why is foreign matter mixed in attention?First, what to do?

The product zone is a term used in a foreign -mixed contamination countermeasure guideline of the American Bread Association (AIB), and is a place where food foods are exposed.If the food foods are exposed and there are foreign substances around or around them, they may enter the food.Therefore, we take measures to identify the place and clean and clean the dangerous places.

There are not so many product zones in the factory.The area is about 20 % of the factory.In other words, if you find only 20 % of this place and take measures intensively, you can get a really high effect.

So how do you do it to accurately identify the product zone?It is necessary to understand the manufacturing process of the factory and draw drawings.This is an example of a pickle factory.

The manufacturing process of this pickled factory is raw material acceptance → refrigerator storage → vegetable plastic surgery → cleaning → pickling → refrigerated → hand -cleaning → weighing packaging → sorting inspection (metal detector) → refrigerator storage → shipping.Write this flow line on the drawing of the factory and identify the product zone.Enter the site and check if there is no missing.

図1:漬物工場の図面上で、プロダクトゾーンを特定するIn this manufacturing process, the food foods are exposed ...

>>第1回 第1章の続きを読む(PDFダウンロード)

Analysis of many food factories tends to occur in 20 % of the problem.The famous parate law (8: 2) also applies to foreign substances in food factories.And 20 % of this problem is in the product zone.If you have identified a product zone that is likely to cause problems, you can further narrow down the problem.

図2:漬物工場の異物混入元分析In the case of the pickle factory in the case, the discovery of the past foreign matter mixed into the factory and the record of the customer complaint was that more than 80 % of the immersion processing process was more than 80 %.

In the pickling process, the worker puts the upper body in a large "tart", lines vegetables from the bottom, salt, and piles the vegetables again.First of all, the hair of the worker, the garbage attached to the work clothes, and the part of the worker's belly always hit the edge of the "tull", so the rim of the edge enters the "tull".

After that, in the process of lying down in the refrigerator and sleeping, the trash and garbage were falling from the top "tull" to the lower "tull".In addition, the air conditioning of the refrigerator was old, the garbage popped out of the outlet and fell into the "tull".It was also found that it was difficult to find foreign matter because the workplace and the inside of the refrigerator were dark.

So, first, to workers in this process ...

>>第1回 第2章の続きを読む(PDFダウンロード)

2nd: Unexpected things to places & tips for layout

In the first edition, we focused on the manufacturing process "Product Zone" where foods are exposed, and explain the narrowing down places where foreign substances are easy to mix and countermeasures.This time, we will introduce the removal of dangerous goods and how to keep the factory clean.

Working supplies used on a daily basis may be mixed into food in an unexpected way and become a "foreign matter".

In one factory, there was a case where the food was mixed with food.When I looked it up, I found that the mixed lint was part of the "string" of the work apron.When you use an apron at home, you rarely care about the apron string.

However, because the factory is used for a long time for a long time, the strings gradually frayed, fell, and entered the food.In this factory, as a countermeasure, we have changed to a vinyl string apron that is not frayed.

In addition, there was a hook that inserted the ballpoint pen in the pocket, and in some cases it was mixed with lunch.When the ballpoint pen was pulled out of the chest pocket, it was thought that the plastic hook was broken and fell into the ingredients.The latest food factory work clothes do not have pockets above the waist.This is the requirement for ISO22002 (food safety management system).By eliminating the pocket itself, the possibility of a foreign matter can be cut off.

Materials such as plastic may fly shards to the distance when cracked.For example, if the caster passes over the ballpoint pen that has fallen on the floor, the debris may splatter and mix into the ingredients.It is effective to change the ballpoint pen to a polypropylene that is less likely to miss it, or hang it from the neck with a string to prevent it from falling.

In addition, an accident in which the plastic board of the device in which the ingredients were pushed into the food cutter had broken.The plastic shards entered the food cutter and discarded all the ingredients in the cutter.

However, the fragments are ...

>>第2回 第1章の続きを読む(PDFダウンロード)

To prevent foreign substances in food, you need to keep the factory clean.By devising the layout of equipment in the factory, it is less dirty and can be cleaned and cleaned effectively.The point of ingenuity is in the gap between the equipment and workbench in contact with the walls and floors.

If the device is in close contact with the wall, dirt is accumulated between the walls and it cannot be cleaned or cleaned.These places quickly become insects, mold, and bacterial hotbeds.To prevent this, do not place anything on the wall side.If there is nothing on the wall side, it is hard to get dirty, and it is easy to clean and clean.

In order to effectively use the factory work space, the workbench may be placed closely on the wall.However, even if you place a workbench in the center of the room and work from both sides, the same work is possible.

If the device or workbench must be placed on the wall side, the distance to the wall is secured by 15 cm or more, and a brush and a cleaning brush will be included in the meantime.In addition, if there is such a space, it is difficult to accumulate moisture, and insects, mold, and bacteria are not established.

If you empty more than 45cm, people will enter.The foreign -mixed entry guidelines of the United States Bread Association (AIB: American Institute of Baking) described that "equipment and workbenches are at least 45 cm from the walls and ceilings."

図2:作業台を中央に配置し、壁側の隙間をなくすNext, the gap between the shelves with food and cooking utensils and the floor.If the lowermost shelf is installed on the floor, the gap cannot be cleaned.It is hard to dry when water gets in, so it cannot be washed.In this case, too ...

>>第2回 第2章の続きを読む(PDFダウンロード)

3rd: Cleaning -Cleaning Kihon

Last time, we explained about the removal of dangerous goods such as lint and plastic pieces, and the tips for keeping the factory clean.This time, we will focus on cleaning cleaning and explain effective procedures, frequency, and foam cleaning.

At a fresh pack factory, we have been conducting bacterial tests for products.And some products were detected in a very close level of bacteria in some products.It was just barely passed.It turned out that the processing of these products is commonly used in multi -slicers.

This multi -slicer is attached to dozens of round blades side by side.The distance between the blades and the blade is only a few mm, and there is a groove that each blade passes.When I looked it up, there was a cause of bacterial contamination in this groove.If you continue to slice the ingredients, bacteria will accumulate in the groove.With the passage of working time, bacteria continued to increase and food was contaminated.

In addition, the disassembly cleaning, which removes all round blades, was not much done because it took time and effort.In order to keep bacterial contamination from worsening, urgent measures were needed.

The countermeasures are simple.It would be nice if the multisrier was always kept clean.First, the cleaning work was divided into two stages: "normal cleaning" and "decomposition cleaning".In normal cleaning, only the blocks of the processing unit are removed, and the rounded blade is set while set.At this time, we verified what kind of cleaning method is effective.On the other hand, in disassembly cleaning, all round blades are removed.In this case, we verified once a week and once a month to see how often it should be done.

As a result, in normal cleaning, ...

>>第3回 第1章の続きを読む(PDFダウンロード)

Foaming (form) cleaning is common sense in Western food factories.Bread factories and noodle factories that use powdered powder and noodle factories cannot be fully foamed, but in other factories, foam cleaning has an excellent effect on countermeasures against foreign substances, including bacteria.It also emerges with foam and removes dirt from fat that is hard to fall off.The washed -off foam flows through the drainage groove, so it is also an insect -proof measure, and the safety management is thoroughly managed.That's not all.Reducing the number of cleaning by brush does not deteriorate the floor and walls, which can also reduce costs, such as reducing working hours and reducing work staff.

Here are the foam cleaning procedures.First, remove the visible garbage.Next, use a foam gun to spray the fine foam of the detergent on the workplace device, the floor, and the wall for a while.After more than 20 minutes, we will wash off the bubbles with water.The last is dry.If the floor is inclined and is easy to drain, just set the air conditioning or dehumidifier timer.If it is difficult to drain and a puddle is formed on the floor, the drainage is applied to drying with an industrial fan.

Video: Foaming and automatic drying measures against foreign substances..HACCP compatible: Foods design creation

There are various types of foam guns for spraying bubbles.Small medium -sized foam guns are suitable for cleaning small places and equipment, and large is convenient for wide -area cleaning, such as the floor and walls of the workplace.First of all, we recommend that you rent a small form gun and try it in a small place.It is a good idea to select it according to the size of the factory and the purpose of cleaning, such as using a small and a large combination of small and large in the stage.

If you propose foam cleaning, the reaction that "cannot be done at our factory" is often returned."The workplace has a cardboard, such as a cardboard, and it is messed up."However, the state itself creates a source of foreign matter mixed.In particular, factories that are not organized in the product zone are dangerous.If you can remove unnecessary things from the workshop and spray the bubbles, you can say that you have taken the first step.

図2:泡洗浄の例It is also important to dehumidify and dry after washing the foam.If you leave the moisture as it is ...

>>第3回 第2章の続きを読む(PDFダウンロード)

4th: Zoning and the use of equipment

Last time, we explained the effective procedures and frequency of cleaning cleaning, and foam washing.This time, we will explain the manufacturing lines and zoning of the factory, and various inspection equipment and removal devices.

By making the factory manufacturing line short and simple, you can balance costs and safety.Not only can the worker's travel distance and the manufacturing time can be shortened, but also the distance and time when the ingredients are exposed, reducing the risk of foreign matter mixed.

But it's not just short.What if you open the cardboard box with raw materials and start preparation right next to it?It is clear that garbage, dust, and insects on the box are mixed into the ingredients and are dangerous.To prevent this, it is necessary to provide a "partition" between the place where the box is opened and the preparation work location.If there is a partition, even if the manufacturing line is short, there is less risk of pollution into the preparation location.

Prevention of crossing pollution.When you think about this throughout the factory, where you should have a partition in the factory, that is, the "zoning" method is a problem.Zoning is to divide the workplace by its hygiene level, such as the “pollution zone”, “quasi -cleanliness zone”, and “clean zone”.

Let's check the method of zoning in the order of manufacturing process.First, raw materials come in from outside the factory.The warehouse that keeps the cardboard box containing raw materials is a "pollution zone" because it is in contact with outside the factory.Next, it is safe to take out only raw materials in the warehouse and move to the preparation room.The preparation room is the "semi -clean zone".After the preparation, move the ingredients to the processing room, cook, cool (when heated), and package.

This process is a "clean zone" that requires the highest hygiene level.This "clean zone" completes all processing, including the inner pack, and will not be newly mixed into the food in the package.

The finished food passes through the inspection process with a metal detector or an X -ray inspection machine and enters the next zoning.It is the "quasi -cleanliness zone" on the shipment side.Here you enter the outer box or container and take it to the shipping warehouse.Finally, it will be shipped out of the factory via the platform (a space to pack the truck).Shipping warehouse and platform are "pollution zone" because they are in contact with outside.

図1:食品の製造動線と、3段階のゾーニングAs mentioned above, I have seen three steps zoning.however,……

>>第4回 第1章の続きを読む(PDFダウンロード)

In the food factory, various foreign -affiliated inspection equipment and removal devices, including metal detectors, are used.Here, we will introduce X -ray testing, permeable inspection machine, and brush removal machine.

First, it is an effective X -ray inspection machine to find foreign substances other than metal.Recently, in addition to miniaturization and high -precision, the price has become cheaper, making it easier to obtain.

In a meat pack factory, bones were mixed.When I tried using an X -ray inspection machine on a trial basis, I found that it could be detected even with a fairly small bone.In addition, since the mixed location can be identified from the monitor video, foreign substances can be removed efficiently.

The many bones were mixed in products, such as shredded meat and minced meat for stewed.Raw material delivery suppliers demanded that they were cautious in the case of bone, and at the same time, they started removing mixed bones at their own factories.Raw materials with a lot of bones are washed away with bacteria -cleaning water (in this case, the surface temperature of the meat rises slightly, so it is sliced in the refrigerator and cooled).To remove the bones and muscles mixed with minced meat, attach the attachment called Bortlimer to the ground meat machine (grinder chopper).When a hard object is mixed, it is automatically selected and removed from the tube in the center of the plate.

In this way, in addition to the introduction of X -ray inspection machines and removal devices, the problem has been visibly reduced due to composite measures such as requesting suppliers.

図3:ボーントリマーとX線検査機next,……

>>第4回 第2章の続きを読む(PDFダウンロード)

5th: Visualization by data & human resource development

Last time, we explained about factory manufacturing lines, zoning, and various inspection equipment and removal devices.This time, I will explain the visualization of inspection and measurement data and human resource development.

Food factories have many tests to check the hygiene of the work environment and the safety of food.In this chapter, we will introduce various tests such as wiping inspections, and explain the danger prediction due to the visualization of data.

Keeping the factory clean will reduce the risk of foreign matter mixed.In order to verify the cleanliness of the work environment, a "wiping test" that can detect invisible pollution, such as bacteria and microorganisms attached to factory equipment and cooking utensils, is effective.

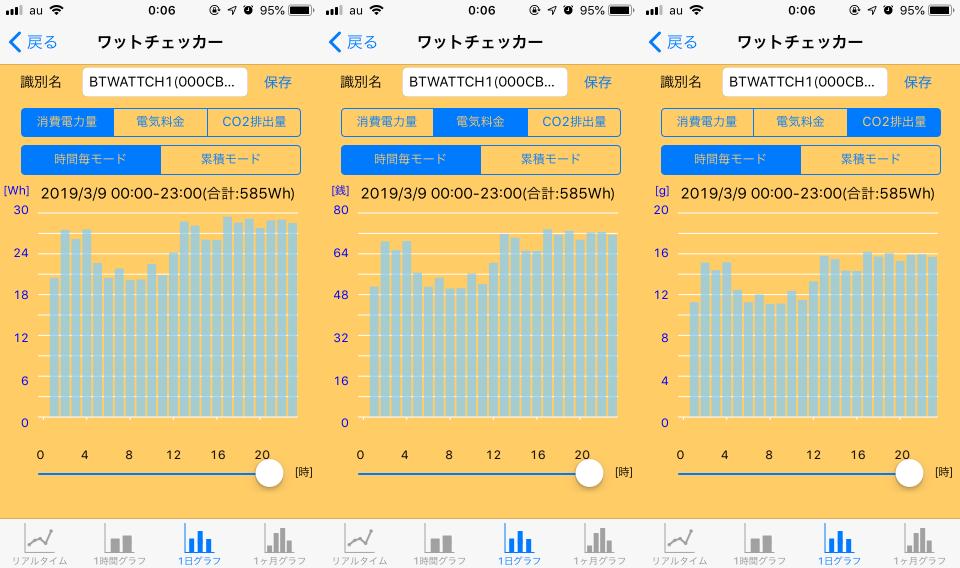

In one factory, a regular ATP test, which is a type of wiping inspection, (a method of emitting light emission by combining ATP (adenosine 3 phosphoric acid) that exists in the cells of all organisms by combining it with enzymes, etc.).We do the same and monitor the trend by graphing the results.

At the beginning of the inspection, the results of the tests conducted everywhere in the factory were poor, and each cleaning procedure was examined and worked on improvement.As a result, a few months later, the numbers began to settle to the safety level.

Then, the average value of the overall was graphed, and we started monitoring trends.For a while, the graph was moving in a safe zone, but suddenly entered a dangerous area.In such a case, you can elucidate the cause by looking at the original data.It turns out that there is a problem with the cleaning results of specific manufacturing equipment.

The newcomer was cleaning instead of a veteran worker in charge of cleaning.Therefore, I arranged the work rotation in a well -balanced manner and solved it.We introduced the "competence system" described later.In this way, monitoring the tendency of the whole and individual inspection data allows for danger detection and analysis.

Next, we will introduce the latest system that monitors trends such as temperature and humidity.The temperature and humidity are related to the safety of the manufacturing site.In a hot and humid environment, mold, insects, and bacteria grow, increasing the risk of mixed with the product.The temperature seems to be measured in many factories.

However,……

>>第5回 第1章の続きを読む(PDFダウンロード)

Even if the latest factory facilities and high -performance inspection systems are introduced, it is "people" that manages and operates them.This chapter describes hygiene education for factory workers and evaluation methods based on the competence system.

Hand washing is very important in a factory that handles food.However, when we conducted a questionnaire survey, there were 20 % of factories with many part -timers who had the question of "why we need to wash their hands to wear gloves."With such a perception, hand washing can be neglected.

Put gloves from the box with a dirty hand and the surface of the gloves will be contaminated.When the gloves are worn, the gloves are already dirty.So you need to wash your hand after wearing gloves.By recognizing this about this, you can follow the rules firmly.It is more important to recognize the fact that the gloves are contaminated rather than hand washing procedures.

The same is true for hair contamination.According to the data of the Japanese hair roots hair loss study group, the average number of hairs per day per Japanese person is 60.If the working hours per day are 8 hours, 20 per person will fall out of the factory if there are 20 per person and 100 workers.If you teach this number, the worker will do the roller firmly.It is more effective to recognize the fact that so many hairs are missing rather than the guidance of "rolling the roller firmly".

Finally, I will introduce the introduction of "competence system".The competence system quantifies how many experience and skills each worker has in the individual work of the factory.for example,……

>>第5回 第2章の続きを読む(PDFダウンロード)

![What is "thousand eyes" at night? [Techniques for listening to jazz - the road to becoming a jazz "professional listener" 126]](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/9b839a325eb3ad18a729c92cc52aa70b_0.jpeg)

![[EV's simple question ③] What is good for KWH, which represents the performance of the battery?What is the difference from AH?-WEB motor magazine](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/b2506c4670f9f2cb45ffa076613c6b7d_0.jpeg)

![[How cool is the 10,000 yen range?] 1st: The performance of the "robot vacuum cleaner with water wiping function (19800 yen)" like Rumba is ...](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/25/5251bb14105c2bfd254c68a1386b7047_0.jpeg)